Alloy grinding head cylindrical code a carbide rotary file

The alloy grinding head cylindrical code A carbide rotary file is a type of cutting tool used for grinding, shaping, and finishing hard materials such...

The alloy grinding head cylindrical code A carbide rotary file is a type of cutting tool used for grinding, shaping, and finishing hard materials such...

Ningbo Gute Hydraulic Co., Ltd. (formerly Yuyao Rifeng Hydraulic Components Factory) is China Alloy Grinding Head manufacturers and wholesale Alloy Grinding Head factory. The company is located in the beautiful Yuyao Simen Industrial Zone, covers an area of 6500 m2, was founded in 1992, is a set design, development, production and sales of hydraulic quick connector, pneumatic quick connector, pipe joint in the integration of enterprises. Established company through continuous innovation and development, and to develop Jiangxi Aike industrial Co., Ltd. covers an area of 30000m2, green coverage of 30%. Products sell well in China, Europe, America, Southeast Asia, Japan, the Middle East and other countries and regions, mainly for engineering, metallurgy, oil, machine tools, military industry and machinery manufacturing and other industries to provide hydraulic and pneumatic products.

Our 30 years of customization experience has created a Gute brand value.

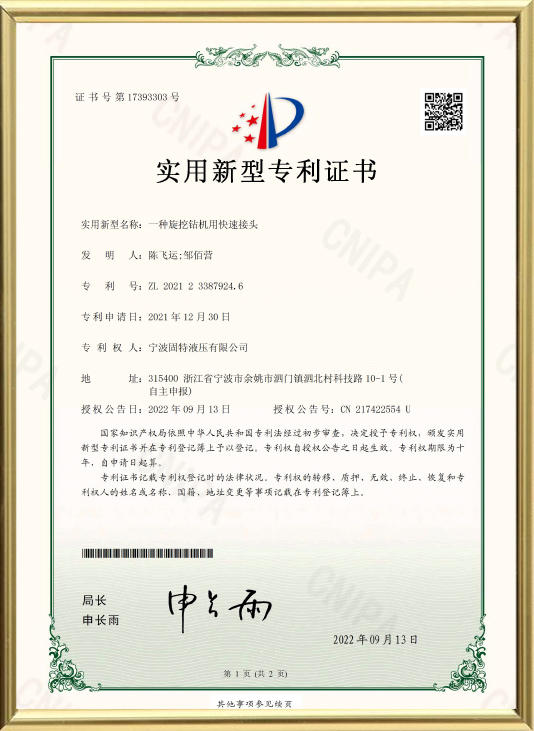

After years of unremitting efforts, the Gute R&D team has achieved a number of technical achievements in the field of hydraulic quick connector manufacturing, and has obtained 9 utility model patents, which guarantee the integrity of the company's technical process and product diversity, and form a deep technical reserve.

GB/T 24001-2016/ISO14001:2015

GB/T 45001-2020/ISO 45001:2018

An Integrated Valve Seat Structure

A New Type Of Flat Quick Connector

A New Type Of Combined Valve Core Structure

A Self-Locking Connection Connector

A Kind Of Quick-Change Joint For High-Pressure Gas

A Quick Connector For Gas

A New Type Of Quick Connector

A Quick Connector With Double Flow Channel Design

A Quick Connector For A Rotary Drilling Rig