GT-A1 Closed type hydraulic quick connector for leakage prevention

The GT-A1 Closed-type hydraulic quick connector is a type of hydraulic fitting designed to prevent fluid leakage from the hydraulic system. It is comm...

The GT-A1 Closed-type hydraulic quick connector is a type of hydraulic fitting designed to prevent fluid leakage from the hydraulic system. It is comm...

The GT-A2 closed-type thread locked hydraulic quick connect coupling sets are a type of hydraulic coupling used to quickly and easily connect and disc...

The GT-A3 close-type ball-locking mechanism hydraulic quick coupling is a type of hydraulic fitting that allows for fast and easy connection and disco...

GT-B1 closed double shut-off hydraulic quick couplings are a type of hydraulic coupling used to connect and disconnect hydraulic lines quickly and eas...

The GT-B2 copper external thread medium pressure high performance gas-liquid quick connector is a type of quick connector used to connect gas and liqu...

The KZD steel internal thread medium pressure gas-liquid quick connector is a type of coupling designed to quickly and easily connect or disconnect th...

KZF is a brand that produces close type pneumatic and hydraulic quick couplings. These couplings are designed to provide a fast and efficient way to c...

GT-C1 ball valve type hydraulic quick coupling is a type of hydraulic coupling used in fluid power applications to quickly connect and disconnect hydr...

● Poppet valves available to prevent uncoupled leakage. ● Poppet valves open automatically when coupled, within rated working pressure, to keep the ...

The GT-CT double-acting sleeve push-and-pull type hydraulic quick coupling is a type of hydraulic coupling used for quick and easy connection and disc...

● GT- FF Series couplings employ flush valving when connecting or disco nnecting.This means that the valves are mated together so that only small am...

The KZE-B thread sleeve locked type high pressure hydraulic quick coupling is a type of hydraulic coupling that is designed for high-pressure applicat...

Ningbo Gute Hydraulic Co., Ltd. (formerly Yuyao Rifeng Hydraulic Components Factory) is China Quick Coupling manufacturers and wholesale Quick Coupling factory. The company is located in the beautiful Yuyao Simen Industrial Zone, covers an area of 6500 m2, was founded in 1992, is a set design, development, production and sales of hydraulic quick connector, pneumatic quick connector, pipe joint in the integration of enterprises. Established company through continuous innovation and development, and to develop Jiangxi Aike industrial Co., Ltd. covers an area of 30000m2, green coverage of 30%. Products sell well in China, Europe, America, Southeast Asia, Japan, the Middle East and other countries and regions, mainly for engineering, metallurgy, oil, machine tools, military industry and machinery manufacturing and other industries to provide hydraulic and pneumatic products.

Our 30 years of customization experience has created a Gute brand value.

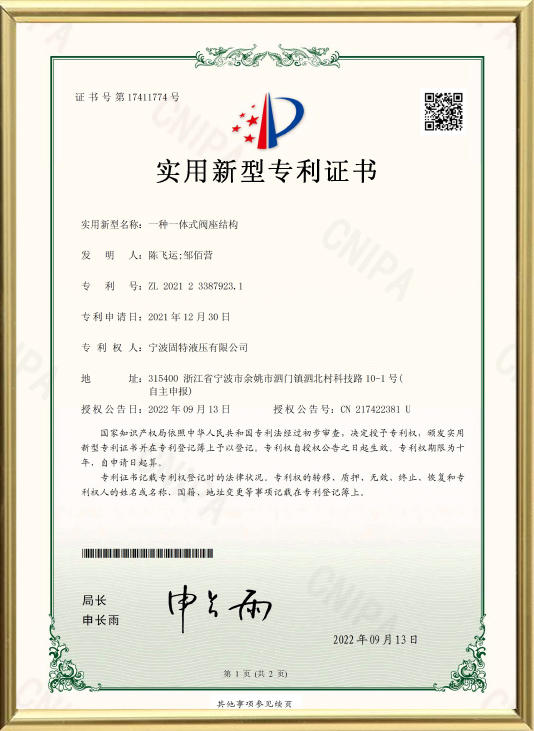

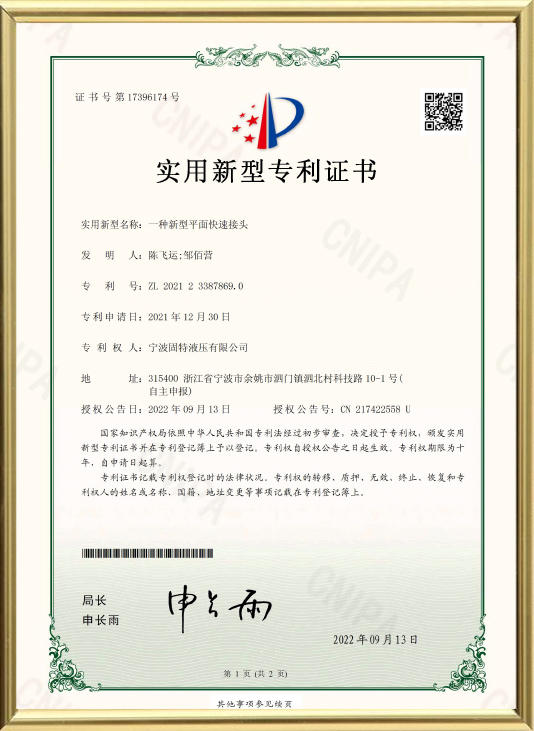

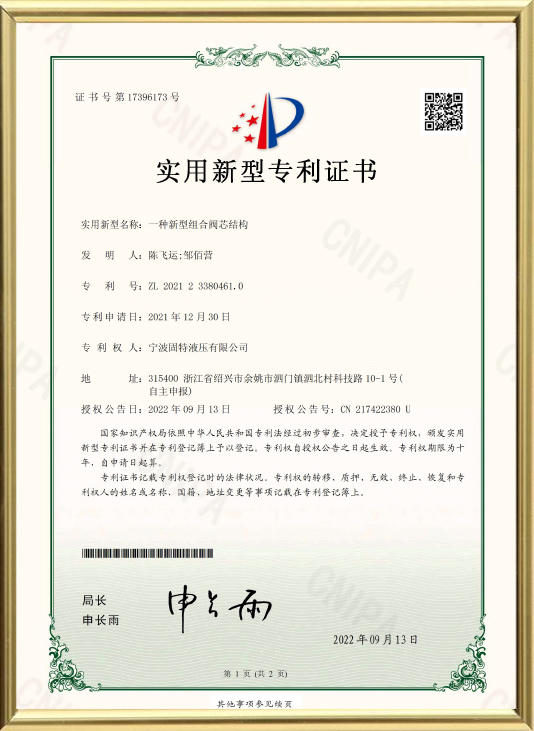

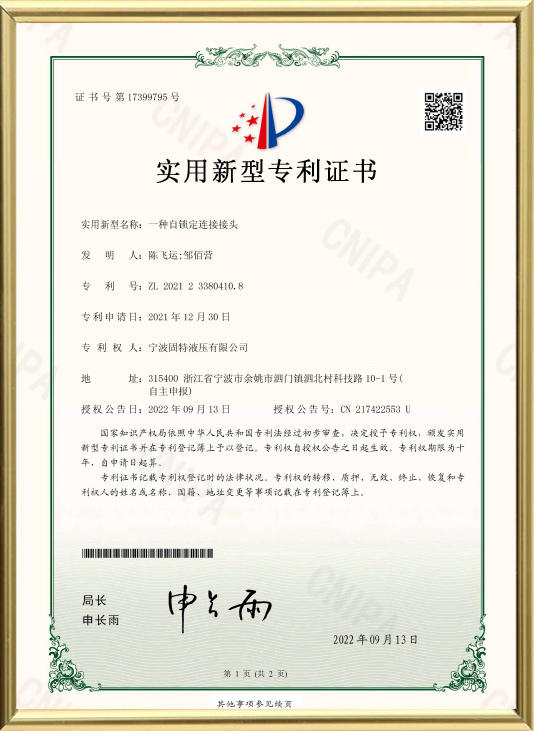

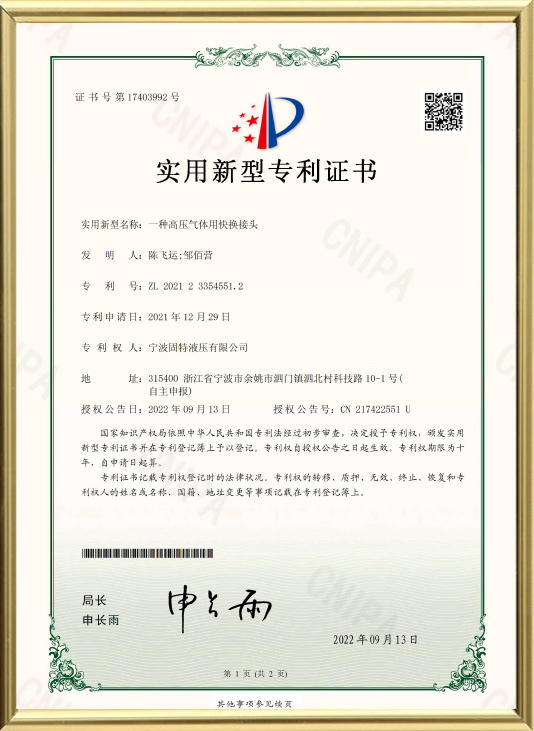

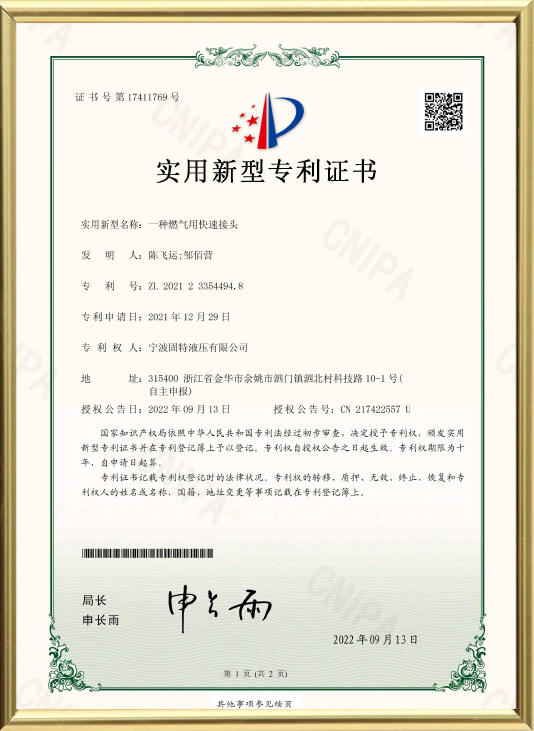

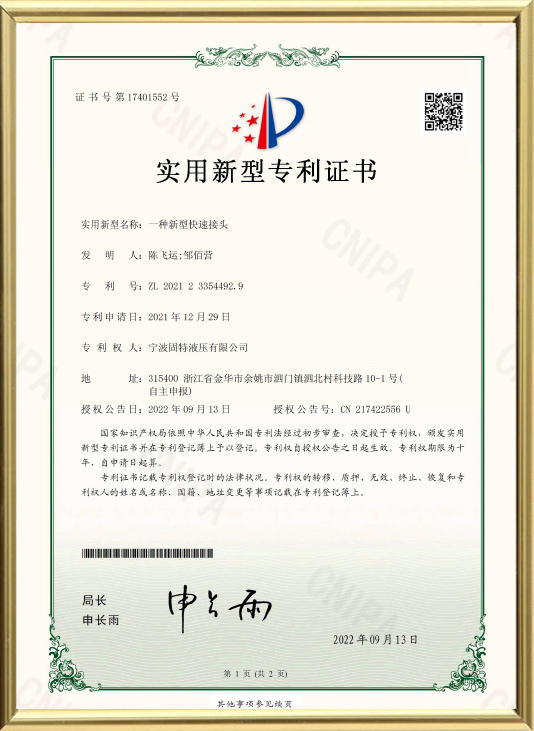

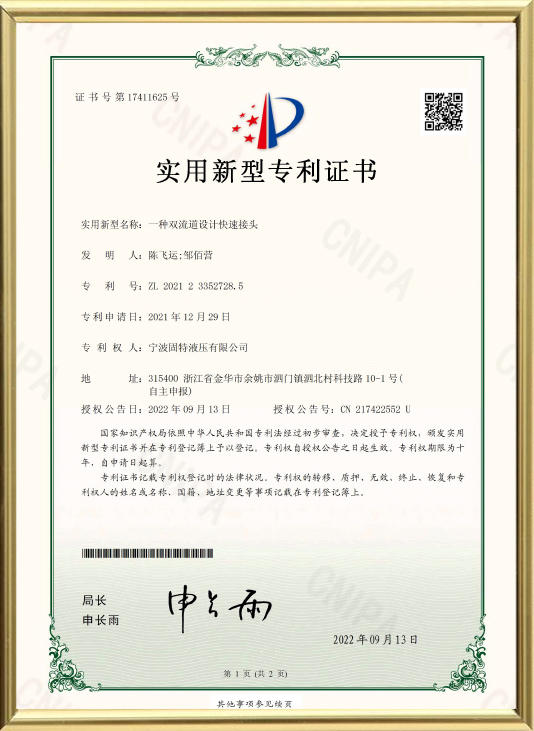

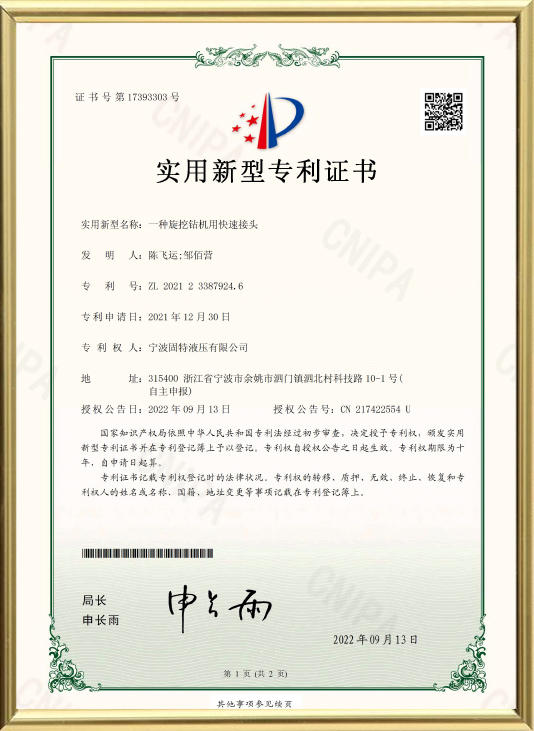

After years of unremitting efforts, the Gute R&D team has achieved a number of technical achievements in the field of hydraulic quick connector manufacturing, and has obtained 9 utility model patents, which guarantee the integrity of the company's technical process and product diversity, and form a deep technical reserve.

GB/T 24001-2016/ISO14001:2015

GB/T 45001-2020/ISO 45001:2018

An Integrated Valve Seat Structure

A New Type Of Flat Quick Connector

A New Type Of Combined Valve Core Structure

A Self-Locking Connection Connector

A Kind Of Quick-Change Joint For High-Pressure Gas

A Quick Connector For Gas

A New Type Of Quick Connector

A Quick Connector With Double Flow Channel Design

A Quick Connector For A Rotary Drilling Rig