Call us

+86-13732136622

+86-15058221666

Stainless Steel Quick Couplers are renowned for their robust material properties, offering far superior strength when compared to couplers made from softer metals such as brass, aluminum, or plastic. The inherent toughness of stainless steel allows these couplers to maintain their structural integrity even under the demanding pressures often encountered in industrial applications. High-pressure systems, such as those found in heavy machinery, require components that can withstand both static and dynamic loads without yielding or deforming. Stainless steel provides excellent resistance to such forces, ensuring that the sealing mechanism stays intact and prevents any deformation or leakage. By comparison, couplers made from weaker materials may experience distortions at connection points under sustained high pressure, which can lead to leakage or failure of the seal over time.

Stainless steel is highly resistant to corrosion, even when exposed to harsh environmental conditions. In industries such as marine, chemical processing, and food processing, where exposure to saltwater, acids, or other corrosive substances is common, Stainless Steel Quick Couplers offer a significant advantage. Stainless steel’s resistance to rust, pitting, and general corrosion ensures that the coupler will maintain its sealing performance and structural integrity, even in highly aggressive environments. In contrast, couplers made from brass or aluminum are more prone to corrosion under similar conditions, which can lead to compromised seals and leaks. Over time, corrosion in these softer materials can weaken the coupler’s sealing capability, reducing its effectiveness and requiring more frequent maintenance or replacement. Stainless Steel Quick Couplers, on the other hand, provide a much longer service life, reducing the need for replacement parts and lowering operational downtime.

The primary function of any quick coupler is to create a secure, leak-free connection. Stainless Steel Quick Couplers excel in this area due to their design and material properties. They typically feature high-quality O-rings, gaskets, and other sealing mechanisms that form a tight barrier against fluid leakage, even under the most demanding pressure conditions. Stainless steel's resistance to wear and damage from environmental factors ensures that these seals remain intact for longer periods of time. Other quick couplers, such as those made from brass or aluminum, may struggle to maintain a reliable seal, particularly under high-pressure fluctuations. With repeated use, seals in non-stainless steel couplers can wear out, dry out, or deform, which increases the likelihood of leaks. Stainless Steel Quick Couplers tend to maintain their sealing capability under extreme conditions such as high-flow systems, where the fluid is under significant pressure. The precision of the seal and its resilience to wear is what truly sets Stainless Steel Quick Couplers apart.

One of the standout features of Stainless Steel Quick Couplers is their ability to handle high pressure without compromising performance. These couplers are designed to withstand extreme pressure levels, exceeding 10,000 PSI (pounds per square inch), depending on the specific application. This makes them highly suitable for industrial and hydraulic systems that require secure connections in high-pressure environments. Stainless steel’s superior tensile strength and fatigue resistance ensure that it remains strong under pressure without failure. In contrast, brass and aluminum couplers, while suitable for medium-pressure applications, have much lower pressure ratings and are more prone to failure under high-stress conditions. The robustness of Stainless Steel Quick Couplers ensures that the sealing function remains intact even under the strain of high pressure, offering a safe and reliable connection.

The durability of Stainless Steel Quick Couplers under repeated use makes them highly effective in applications with constant wear and tear, such as construction, manufacturing, and mining. Stainless steel’s hardness provides resistance to abrasion and damage, ensuring that the coupler’s sealing surfaces do not wear down quickly, even with continuous use. Unlike brass or aluminum couplers, which may experience surface degradation over time—especially in environments with abrasive fluids or particulate matter—stainless steel maintains a consistent sealing performance for extended periods. Frequent use of couplers in high-pressure systems can lead to material fatigue in lower-quality couplers, which compromises their sealing ability. Stainless steel, however, exhibits minimal wear over time, providing a longer-lasting, maintenance-free solution.

The GT-A2 closed-type thread locked hydraulic quick connect coupling sets are a type of hydraulic coupling used to quickly and easily connect and disc...

See Details

The GT-CT double-acting sleeve push-and-pull type hydraulic quick coupling is a type of hydraulic coupling used for quick and easy connection and disc...

See Details

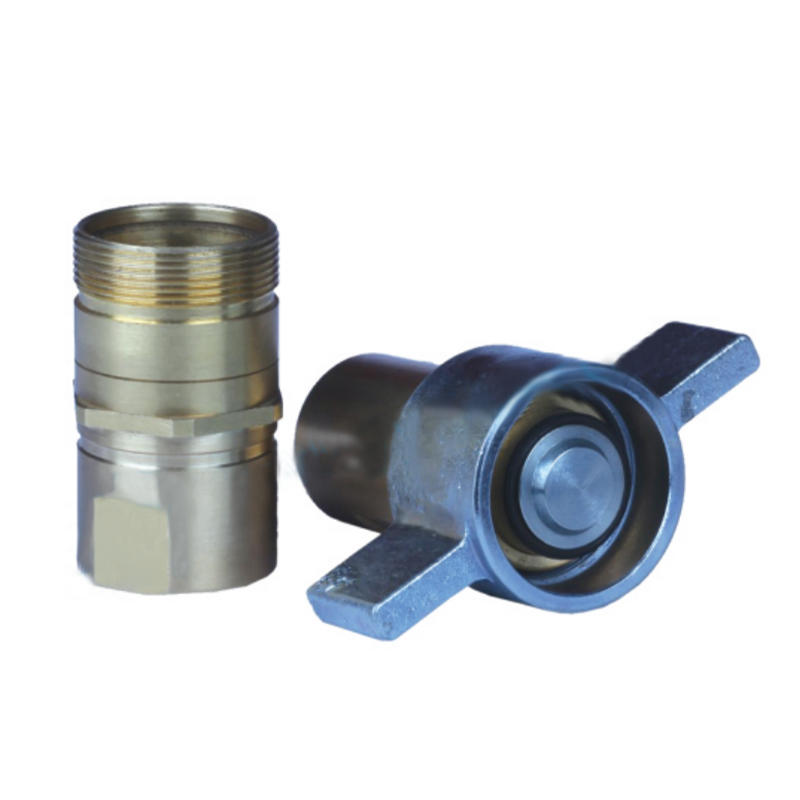

The GT-L2 Heavy-Dust Wing Nut Thread Type Hydraulic Quick Coupling is a type of hydraulic coupling used to connect and disconnect fluid lines quickly ...

See Details

The KZE-B thread sleeve locked type high pressure hydraulic quick coupling is a type of hydraulic coupling that is designed for high-pressure applica...

See Details

● The smooth, open bore with no valving in either half offers minimal pressure drop and allows easy cleaning in applications where the same lines are...

See Details

GT-MA High flow brass quick coupling mould is a type of mold used in the manufacturing of high-quality brass quick couplings. This type of mold is typ...

See Details

QKD153 Steel Single disconnect pneumatic quick air fittings are a type of air fitting used to connect and disconnect pneumatic hoses or tubes quickly ...

See Details

KZE-B Hydraulic Coupler Dust Cap and Plug Cover is an accessory used to protect hydraulic couplers from dust, dirt, and other contaminants when they a...

See Details

The YJZQ-G1 carbon steel white galvanized high pressure hydraulic ball valve is a type of ball valve that is used in high-pressure hydraulic systems. ...

See Details

Contact Us