Call us

+86-13732136622

+86-15058221666

The Quick Release Coupling incorporates a sophisticated, engineered locking mechanism that ensures a secure and tight connection between the coupling halves. This mechanism typically features a spring-loaded or collar-lock design that, once engaged, holds the two coupling components together firmly. This secure connection prevents the coupling from disconnecting due to external forces like vibration or shock. Whether the system is under normal operating conditions or exposed to sudden impacts, the locking mechanism ensures that the coupling remains intact. In applications where fluid flow or gas transfer is critical—such as in hydraulic systems, fuel lines, or pneumatic equipment—the coupling’s ability to resist accidental disconnection is paramount for maintaining system performance, safety, and integrity.

To withstand the mechanical stresses inherent in environments with vibration, shock, and movement, Quick Release Couplings are fabricated from high-strength, corrosion-resistant materials. Commonly used materials include stainless steel, brass, and composite alloys, each chosen for its specific resistance to wear, fatigue, and impact. Stainless steel, for example, provides superior resistance to corrosion, high tensile strength, and longevity in harsh environments. Brass is particularly well-suited for applications where lower weight is desired without sacrificing strength, while composite alloys are used in industries where both light weight and impact resistance are crucial. The materials used ensure that the coupling can withstand the wear and mechanical stresses that come with repetitive vibration, ensuring that it performs consistently over time without degradation.

The design of the Quick Release Coupling is specifically optimized to mitigate the effects of shock and impact, which are commonly encountered in heavy machinery or mobile equipment. Many couplings are equipped with shock-absorbing components or reinforced housings that absorb the energy from sudden impacts. This cushioning prevents damage to the coupling's internal components, maintaining its structural integrity and prolonging its service life. For example, certain couplings feature rubber inserts or spring-loaded seals that provide extra protection against impacts. The coupling’s design ensures that even if it is subjected to rough handling, dropping, or sudden jarring, its components do not suffer from deformations or failures, which could otherwise compromise its sealing function and overall performance.

The Quick Release Coupling’s design ensures that once it is connected, it remains secure under conditions of vibration and mechanical movement. Unlike threaded couplings, which may loosen over time due to continuous vibration, the Quick Release Coupling uses a tight fit and an integrated locking mechanism to resist loosening. The design ensures that the coupling halves stay firmly engaged even under harsh conditions, maintaining a stable, leak-proof connection despite any external forces. The internal seals and the coupling’s overall locking mechanism work in tandem to resist the loosening effects that vibration can cause.

One of the most important factors for the performance of any coupling in a dynamic environment is the longevity and integrity of its seals. The Quick Release Coupling is engineered to minimize stress on its seals during both connection and disconnection. Seals, often made from high-quality elastomers, are designed to maintain their flexibility and sealing capability under the stress of repeated connections and vibrations. The coupling design prevents excessive deformation of the seals, even during rapid engagement or under fluctuating pressures. Many Quick Release Couplings feature dynamic seals that retain their sealing ability even when subjected to continuous movement or vibrations, ensuring that the connection remains leak-proof and operational. This careful attention to seal performance reduces the likelihood of wear or degradation, ensuring reliable and consistent performance throughout the coupling's service life.

The GT-CVV manual thread locked type high flow hydraulic quick coupling is a type of hydraulic connector used to quickly and easily connect and discon...

See Details

The GT-VVS Steel thread locked type chrome plating hydraulic quick coupling is a type of hydraulic coupling used in hydraulic systems. These couplings...

See Details

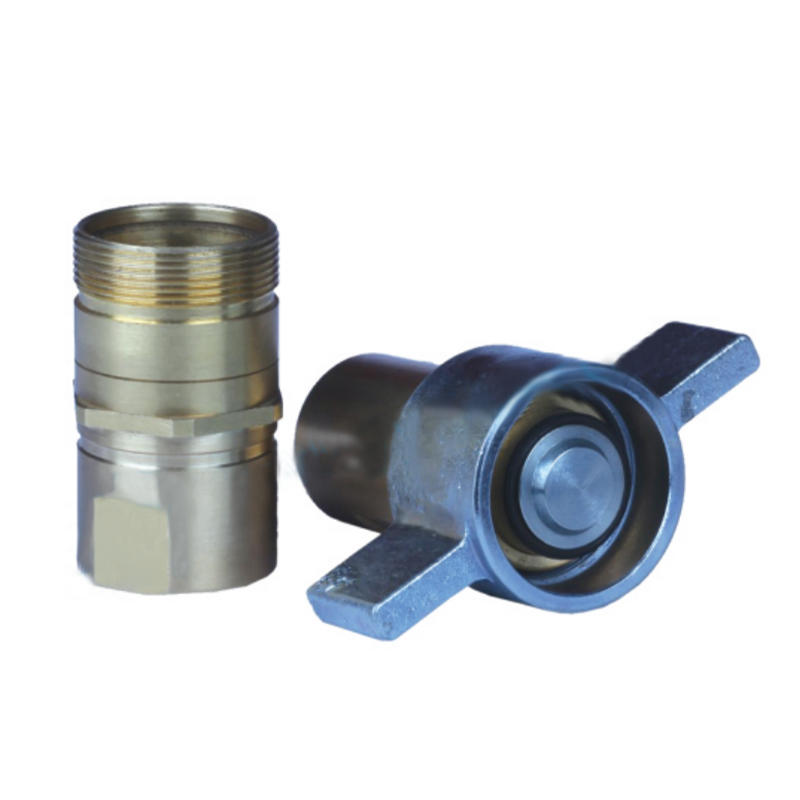

The GT-L2 Heavy-Dust Wing Nut Thread Type Hydraulic Quick Coupling is a type of hydraulic coupling used to connect and disconnect fluid lines quickly ...

See Details

● Positive valve stop, the perch maintains valve alignment and provides metal to metal valve stop to ensure that the valves openfully, every time. ● P...

See Details

Material: Carbon Steel Plating: Chrome Plated Temperature Range (Nbr): -20°C + 100°C Thread Size: Dn10 Dn12.5 Dn20 Dn25 Dn31.5 Thread: M18*1.5 M22*1....

See Details

Metal Parking Station For Socket GT-VF Series Quick Couplings.

See Details

The QKD-X MINI Type single-handed and semi-automatic pneumatic quick coupling is a type of air fitting that allows for quick and easy connection and d...

See Details

KZE-B Hydraulic Coupler Dust Cap and Plug Cover is an accessory used to protect hydraulic couplers from dust, dirt, and other contaminants when they a...

See Details

The YJZQ-G1 carbon steel white galvanized high pressure hydraulic ball valve is a type of ball valve that is used in high-pressure hydraulic systems. ...

See Details

The YJZQ-G1 carbon steel white galvanized high pressure hydraulic ball valve is a type of ball valve that is used in high-pressure hydraulic systems. ...

See Details

Contact Us